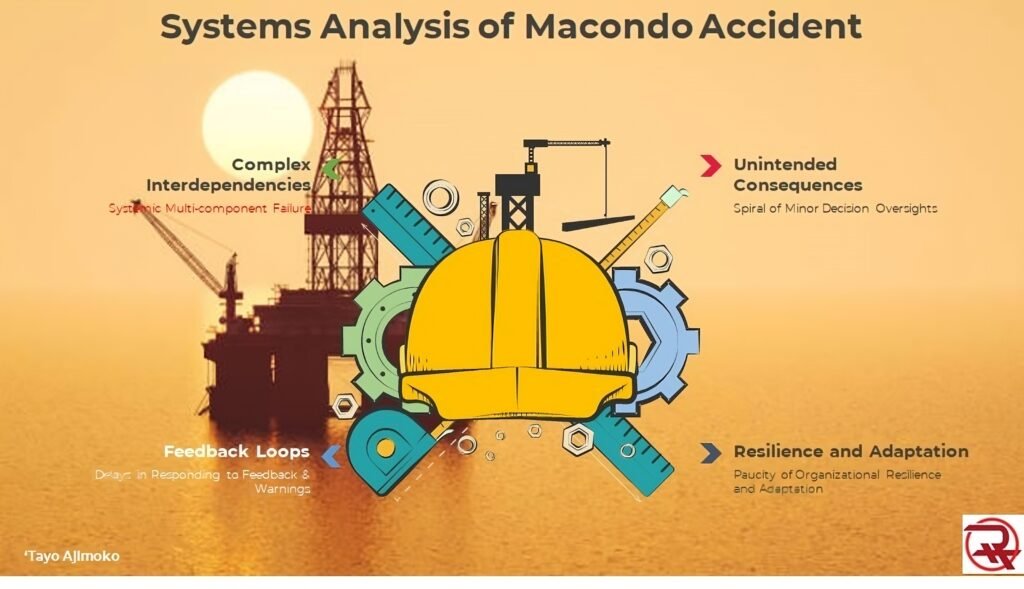

Applying systems thinking to analyze the Deepwater Horizon Macondo accident reveals several interconnected lessons:

Systems Analysis of the Accident

Complex Interdependencies:

The accident was not caused by a single factor but by a complex web of interdependent elements, including human factors, mechanical failure, and organizational culture. From a human factors’ perspective, normalisation of deviance was one of the root causes. Automation can probably help squeeze out normalisation of deviance but until that can be proven, strong leadership culture promoting a zero-tolerance approach to cutting corners is the best protection. Each component influenced the others, highlighting the need to consider the entire system when assessing risk.

Feedback Loops:

Feedback loops played a critical role in exacerbating the situation. The accident highlighted that multi-part risk management between an operator and a drilling contractor requires better role clarity and more oversight. For example, inadequate communication and coordination between different parties involved in the operation led to delays in recognizing and responding to warning signs. Understanding these feedback loops is essential for preventing similar accidents in the future.

Unintended Consequences:

The accident demonstrated how seemingly minor decisions or oversights can have significant unintended consequences. For instance, cost-cutting measures and schedule pressures may have compromised safety protocols, leading to catastrophic outcomes. Anticipating and mitigating such unintended consequences requires a holistic understanding of the system dynamics.

Resilience and Adaptation:

Despite extensive safety protocols and risk assessments, the system failed to prevent the accident. This highlights the need for organizations to build resilience and adaptability into their systems. By continuously monitoring and adjusting to changing conditions, organizations can better respond to unexpected events and minimize their impact.

In essence, applying systems thinking to the Deepwater Horizon Macondo accident underscores the importance of considering the interconnectedness of factors, understanding feedback loops, addressing unintended consequences, and fostering resilience in complex systems to prevent similar disasters in the future.

Mitigations and Actions to Prevent Recurrence

Lesson 1: Complex Interdependencies

- Digital Twin Technology: Develop digital twins of drilling operations and equipment to model and simulate complex interdependencies between various components. Digital twins can provide real-time insights into how changes in one part of the system affect the overall operation, enabling proactive adjustments.

- IoT-Enabled Sensor Networks: Deploy IoT sensors throughout the drilling infrastructure to capture data on environmental conditions, equipment performance, and operational parameters. This data can be analyzed to identify and understand complex interdependencies between different subsystems.

- Big Data Analytics: Utilize big data analytics to process and analyze large volumes of data from diverse sources, including geological surveys, drilling logs, and equipment telemetry. Advanced analytics techniques like machine learning can uncover hidden patterns and relationships within the data, revealing complex interdependencies.

Lesson 2: Feedback Loops

- Predictive Maintenance Systems: Implement predictive maintenance systems that use machine learning algorithms to detect early warning signs of equipment failure and initiate preventive measures. By closing the feedback loop between equipment performance and maintenance actions, organizations can minimize downtime and maximize operational efficiency.

- Real-Time Performance Monitoring: Develop real-time monitoring systems that track key performance indicators (KPIs) and provide instant feedback to operators and decision-makers. Dashboards and visualization tools can display KPI trends and anomalies, enabling timely interventions to optimize performance.

Lesson 3: Unintended Consequences

- Implement AI-Powered Risk Prediction: Utilize machine learning algorithms to analyze historical data and identify potential risks in drilling operations. This technology can predict and prioritize risks, allowing for proactive mitigation measures.

- IoT-Enabled Monitoring Systems: Deploy IoT sensors on drilling equipment to continuously monitor critical parameters such as pressure, temperature, and flow rates in real-time. This data can be analyzed to detect anomalies and trigger automatic shutdowns or corrective actions.

- Scenario Planning and Simulation: Use advanced simulation techniques to model different scenarios and assess the potential unintended consequences of operational decisions. By simulating various scenarios, organizations can anticipate and mitigate risks before they manifest.

Lesson 4: Resilience and Adaptation

- Agile Project Management: Adopt agile project management methodologies to enhance organizational resilience and adaptability. Agile frameworks like Scrum and Kanban enable teams to respond quickly to changing circumstances and deliver value incrementally.

- Collaborative Decision-Making: Establish collaborative decision-making platforms that enable cross-functional teams to collaborate effectively and make informed decisions in dynamic environments. These platforms facilitate rapid information sharing, consensus-building, and adaptive decision-making.